April 3, 2024

April 3, 2024

Engineers consistently grapple with unique challenges when it comes to accurately measuring weight. And sometimes, off-the-shelf load cells simply cannot rise to the location.

That’s when custom-weight devices come to play their part. They bring flexibility to the project, allowing the space to create a weighing solution that fits perfectly inside the demand of your project.

With our team of engineers with a large background in weight, Massload is famous for helping you find the best solution for your project to have accurate, safe, and easy-to-operate weight measurements.

In this article, you can learn how custom load cells help overcome these challenges, offering tailored solutions to meet the diverse needs of various industries, such as cement, oil and gas, mining, construction, agriculture, and more.

Understanding Weighing Challenges

While off-the-shelf load cells are functional in many scenarios, their generic design may not adequately address the specific demands of industrial applications, leading to compromised accuracy and reliability.

In some cases, like mixing concrete in plants or monitoring the load that tension equipment can handle, load cells designed specifically for that job are needed.

The Role of Custom-Designed Load Cells

Enter custom load cells—a game-changer in industrial weighing solutions.

Unlike their off-the-shelf counterparts, custom load cells are meticulously designed to address the unique requirements of each application, offering a level of precision and reliability unmatched by standard solutions.

Custom-designed load cells cater to various industrial needs, from load pins capable of withstanding extreme pressures in mining operations to tension links designed for precise force measurement in OEM machinery.

How Custom Load Cells Address Unique Weighing Challenges?

There are plenty of stories about how tailor-made load cells have revolutionized industrial weighing.

Let´s talk about some of them:

Tailored Solutions for Diverse Environments

Custom load cells are meticulously engineered to withstand harsh environmental conditions commonly found in industries such as mining, oil and gas, and agriculture.

Precision in Specialized Measurements

Custom load cells excel in applications requiring highly specialized measurements, such as precise batching in cement plants or tension monitoring in OEM machinery.

Overcoming Limitations of Standard Load Cells

Unlike off-the-shelf load cells, custom load cells for weighing address the limitations imposed by generic designs.

Design Considerations for Optimal Performance

Designing custom load cells involves carefully considering factors like accuracy, precision, environmental compatibility, and compatibility with existing systems.

Benefits of Collaboration with Custom Load Cell Manufacturers

Partnering with specialized manufacturers like Massload offers numerous advantages.

Quality Assurance and Compliance

Custom load cell manufacturers adhere to stringent quality assurance and compliance measures to ensure product quality and regulatory adherence.

Massload Custom Load Cells

Our custom load cell products—load cells, load pins, and tension links—offer specific advantages and capabilities designed to address a range of weighing challenges.

Here’s a closer look at each product:

Custom Load Cells

Our custom load cells are engineered with precision and expertise to provide accurate and reliable measurements in diverse industrial environments. Here’s what sets them apart:

- Robust Construction: Constructed with high-quality materials, our custom load cells for weighing are built to withstand harsh conditions, including extreme temperatures and corrosive substances.

- Versatility: From heavy-duty weighing applications in mining operations to precise force measurement in OEM machinery, our custom load cells offer versatility across various industries.

- Customization Options: With customizable size, shape, material, and calibration options, our custom load cells can be tailored to meet the specific requirements of each application.

Custom Load Pins

Our custom load pins are designed for applications that require precise force measurement in tight spaces or unconventional configurations. Here’s why they’re the ideal solution:

- Compact Design: Their compact size allows custom load pins to be easily integrated into existing equipment and systems without requiring extensive modifications.

- High Accuracy: Despite their small size, our custom load pins deliver accurate and reliable measurements, ensuring optimal performance in challenging environments.

- Durability: Built to withstand heavy loads and harsh conditions, our custom load pins are engineered for long-term durability and reliability.

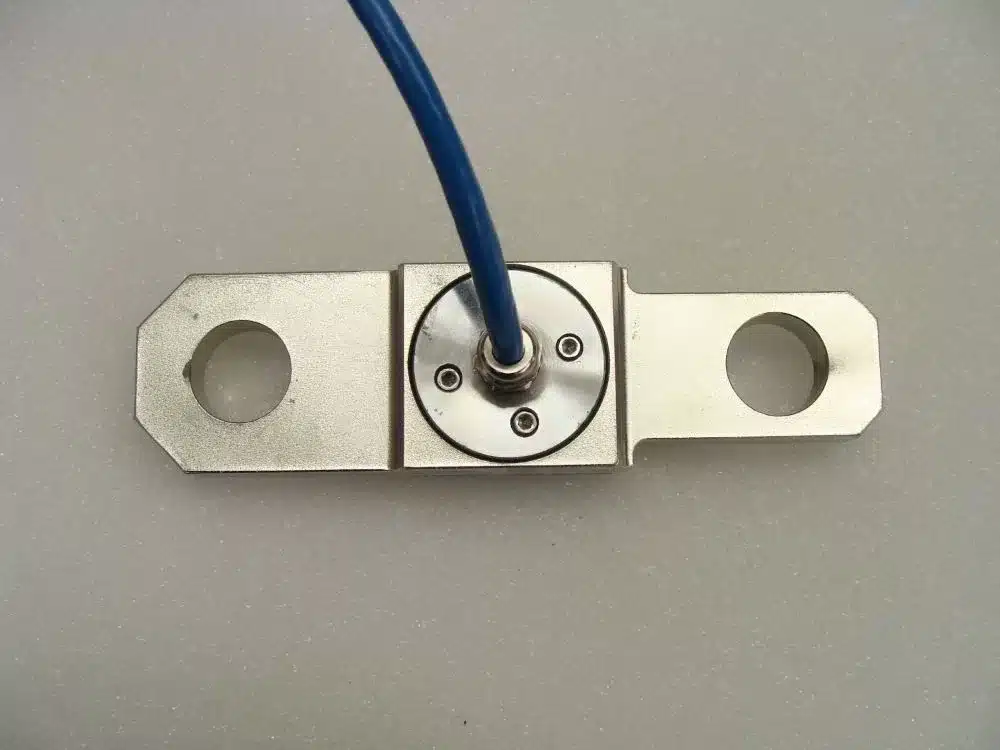

Custom Tension Links

We’ve crafted our custom tension links with a focus on measuring the pull or force in cables, wires, and other systems that need tightening. Here’s what makes them stand out:

- Precise Tension Measurement: they provide precise measurements of tension or force, allowing for accurate monitoring and control.

- Easy Installation: Our custom tension links are designed for easy installation and integration, minimizing downtime and disruption to operations.

- High Load Capacity: Built to handle high loads, our custom tension links can measure tension in even the most demanding applications.

Case study: Custom Load Cells in Action

Let’s take a closer look at how custom load cells have revolutionized weighing processes in real-world scenarios.

In a recent case study, Massload partnered with a client in the oil and gas industry to address a pressing challenge: accurately measuring natural gas flow in a desander system is key to getting it right.

Thanks to special load cells built tough for the rough ride in desander setups, our client now enjoys spot-on accuracy and trusty performance like never before.

Imagine turning your biggest headaches in measuring weights into victories. That’s exactly what happened here, thanks to innovative thinking with custom load cells for weighing.

Eager for more? Read the complete case study here.

When thinking about which load cell to choose for your project, it is important to remember that off-the-shelf solutions, while useful in many cases, often fall short when faced with the unique demands of various industries.

Custom design is required when the customer needs a load cell or scale product that does not currently exist and seeks a vendor to design a new product.

This is where custom load cells step in, offering a tailored approach to measurement challenges. They are carefully crafted weight measurement devices that are engineered to fit perfectly inside your project.

From the rough terrain of mining operations to the intricate processes of cement plants, custom load cells are designed with precision and expertise to meet specific requirements.

Partner With Massload for Your Custom Load Cells and Industrial Weighing Solutions

Our in-house engineering and product specialists are available to custom design a load cell or industrial weighing scale to your unique requirements, and Massload’s dedicated after-sales customer support and service personnel are here to ensure your industrial weighing solution will continue to perform year after year.

When you partner with Massload, our team of product designers and test engineers becomes an extension of your team to ensure you get exactly what you need when needed.

Your vision becomes our vision. Your success becomes our shared success.