Crane Scales, Lifting & Hoisting

Massload Technologies specializes in the design and manufacture of high quality strain gauge transducers and products for the crane, construction, lifting and hoisting industry.

Tension Load Cell Dynamometer

Support local manufacture with Massload's rugged and reliable industrial grade ML-700 Tension Link model ranges from 10,000 lbs to 250,000 lbs, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Output options include cabled, wireless, 4-20mA, 0-10V, 0-5V, +/- 10V and ATEX. Common applications include load lifting, and line tension measurement.

Custom Tension Load Cell Dynamometer

Support local manufacture with Massload's Custom Tension Links, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. They are professionally engineered and stamped based on your exact technical requirements. Options include cabled and wireless, mV/V, 4-20mA, 0-10V, 0-5V, +/- 10V. Common applications include mine workstage galloways, hoist rope attachments and crane modernizations.

Hanging Crane Scale

Massload's provides a range of imported Hanging Crane Scales from 60,000 lbs to 40,000 lbs with Infra-red Remote Control

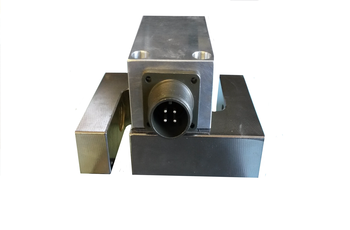

Custom Load Pin

Load Pins typically replace the clevis or sheave pin in a lifting or supporting device. They are ideal when head room is limited. As a safe load indicator, our Custom Load pins are professionally engineered and stamped based on your exact technical requirements. Support local manufacture with Massload's Custom Load Pins, made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Options include cabled and wireless, mV/V, 4-20mA, 0-10V, 0-5V, +/- 10V. Common applications include clevis pins for mine workstage galloways, hoist rope attachments, crane modernizations, material handling and paper mills.

Wireless & Wired Load Shackle

Support local manufacture with Massload's rugged and reliable industrial grade Wireless and Wired Load Shackles ranging from 6.5t to 55t, comprising stainless steel Load Pins and Bobbins, and rugged HDPE wireless enclosures fully manufactured and calibrated in-house with Crosby shackles and through our VCAP certified Quality Management System. Output options include cabled, wireless, 4-20mA, 0-10V, 0-5V, +/- 10V and ATEX. Common applications include load lifting, and line tension measurement.

S-Type Tension Compression Load Cell

Massload offers a high quality industrial grade S-type load cell of 10,000 lbs capacity with quick disconnect box for oilfield applications. We also supply a full range of S-type imported load cells for applications such as tank and hopper weighing.

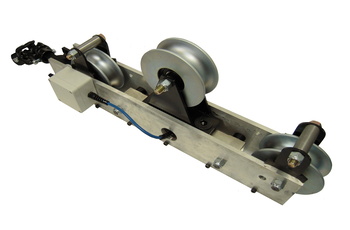

Floating Running Line Tensiometer

Support local manufacture with Massload's rugged and reliable industrial grade Floater Cable Tension Monitor Crane Scale with model ranges supporting wire rope diameters from 0.5" to 1.5". Made with the highest quality materials and fully manufactured and calibrated in-house through our VCAP certified Quality Management System. Output options include cabled, wireless, 4-20mA, 0-10V, 0-5V, +/- 10V. Common applications include crane boom, cable ferry, and line tension measurement.

Dead End Wireline Tension Monitor

Support local manufacture with Massload's rugged and reliable industrial grade Dead-End Cable Tension Monitor Crane Scale with model ranges supporting wire rope diameters from 0.75" to 2.0". Made with the highest quality materials and fully manufactured in-house through our VCAP certified Quality Management System. Output options include cabled, wireless, 4-20mA, 0-10V, 0-5V, +/- 10V and wireless. Common applications include oilfield wireline tension measurement.

Rope Attachments

Massload designs and manufactured a range of rope attachments including clevises, clevis pins, threaded clevis pins, spacer plates, etc. for mining and industrial applications.

Benefits & Applications

Imagine the complexity of hoisting massive loads high above a busy construction site or managing inventory in a huge warehouse.

Crane scales make these daunting tasks possible, making sure that each lift is within safe weight limits and streamlining operations across multiple construction sites.

What is a Crane Scale?

A crane scale is a vital tool in the lifting and hoisting industry that measures the weight of a load.

Knowing the weight of what you’re lifting is key, whether it’s a high-rise construction project or a precision manufacturing process.

In construction, they ensure materials are lifted safely. In manufacturing and warehousing, they streamline production and inventory management. For weighing logistics they ensure cargo is weighed correctly for compliant transportation.

What Are the Benefits of a Crane Scale?

- Safety First: They ensure that loads are within safe lifting capacities, reducing the risk of accidents.

- Operational Efficiency: Crane scales help with resource planning and logistics management by weighing accurately.

Crane Scale Types

Massload Technologies has a range of crane weighing systems to suit heavy industries. Let’s look at the product line:

Heavy-Duty Crane Scales

For the toughest lifting jobs our heavy-duty crane scales are built tough with the latest technology and can handle up to 250,000 lbs, so your heavy lifting is done safely and accurately.

Spotlight on our innovative solution:

Wireless Crane Scales

Embrace flexibility and ease of use with our wireless crane scales. Say goodbye to cables and hello to streamlined operations whether on the factory floor or in the field.

Featuring our standout product:

Portable Crane Scales

Mobility without compromise. Our portable digital crane scales are compact for on-the-go weighing without sacrificing accuracy or reliability.

Bespoke options include:

Customized Measurement Solutions

Crane Scales aren’t one-size-fits-all solutions. On special applications, you can count on our team to help you find the right weighing solution.

Products made just for you:

Dynamic and Static Monitoring Systems

Our dynamic and static monitoring systems are designed for continuous and accurate monitoring for various applications.

Specialized Accessories

Boost your crane scale’s utility and efficiency with our specialized accessories to elevate safety and performance in any setup.

Highly recommended:

Key Features of Massload’s Crane Scales

What sets Massload apart? We deliver the best for our customers and partners!

High Accuracy and Precision

Advanced sensors and calibration for precise measurements your operations rely on.

Durability and Reliability

Built to last, ready for the toughest environments and consistent performance every day.

User-Friendly Interface

We believe technology should simplify not complicate. Our crane scales have simple controls and displays so accurate weighing is easy to do every day.

Industries Served

Massload’s expertise covers many industries and offers solutions for operational safety and efficiency.

Get to know some of them:

Mining

Our crane scales are built to withstand the harsh conditions of mining operations, for precise weight measurement, resource extraction, and transportation while offering:

- Accurate payload tracking for efficiency and compliance.

- Durable designs suited for harsh mining environments.

- Enhanced operational safety with reliable weight data.

Oil & Gas

The oil and gas industry needs equipment that can perform under pressure. Our scales are designed to deliver the precision required for exploration, drilling, and production while providing:

- High precision for safety and regulatory compliance.

- Robust construction for challenging oilfield conditions.

- Critical support for logistics and supply chain management.

OEM

Original Equipment Manufacturers (OEMs) require precise components that integrate seamlessly into their products.

Our Crane Scales Can Be Customised To Suit OEM Requirements As Well As:

- Seamless integration through customization.

- Precision engineering for reliable performance.

- Durable designs that enhance product value.

Lifting and Hoisting

In lifting and hoisting operations there’s no room for error. With features for ease of use and durability, our crane scales help operators ensure loads are within safe lifting capacities, preventing overloading, accidents, and:

- Accurate weight measurements for safe lifting operations.

- User-friendly interfaces for efficient operation.

- Robust construction for long-term reliability.

Vehicle Recovery

Vehicle recovery operations require quick decisions in tough conditions. Our crane scales are portable and tough to use in the field where conditions are unpredictable. Our crane scales:

- Portable designs for field operations.

- Precise weighing for effective vehicle recovery.

- Durable and reliable under tough conditions.

Construction and Engineering

Our scales measure materials precisely, for structural integrity and project efficiency. From material transport to final construction stages, our solutions are part of keeping projects on track and on budget and:

- Precision for material weighing and budget management.

- Durable scales for rugged construction sites.

- Support for project efficiency and compliance.

Shipping and Logistics

Our crane scales have the precision for accurate cargo weighing, load distribution and:

- Precision weighing for regulatory compliance.

- Support for efficient load planning and distribution.

- Robust and reliable for the logistics environment.

Technical Specifications

Load Capacity Range

Our crane scales are working hard from construction sites to manufacturing floors. Their cargo range is up to 250,000 lbs (113 tons) and custom options are available.

Dimensions and Form Factors

Scales come in various sizes and styles to fit your lifting equipment.

Connectivity Options

Wired or wireless connectivity to connect to your data management systems.

Ready to Elevate Your Weighing Solutions? Contact Massload Today!

With Massload, you can always count on our unwavering commitment to excellence. We’re here to support your operations with high-quality, reliable crane scales.

Searching for the perfect crane scale for sale? Complete the ‘Request a Solution’ form below asking for a quote, and we will contact you as soon as possible.

Frequently Asked Questions About Crane Scales

What Display Features Are Available on Massload Crane Scales?

The most common display used for wireless crane scales is the Massload 2.4Ghz Wireless hand held single channel load cell weight indicator.

This wireless portable display receiver provides an 8-digit LCD reading from any of the T24 transmitter modules, including strain gauge, current, voltage, temperature, pulse, or potentiometer.

The remote handheld wireless receiver module can be automatically powered on and off as the T24-HS handheld is operated. Status indicators notify the user of input integrity issues, low battery, low signal, over range, or other errors in the remote transmitter module.Its main features are:

- Two key operation offering tare functionality

- Can communicate with a wireless load cell transmitter or Massload wireless scales

- Single channel and 12 channel models available

- 2.4 Ghz radio link

- Wireless range of up to 800 m (2,600 ft) open field site

- Power: 2 AA replaceable batteries

- Battery powered 40 hours continuous use

- Auto ‘power on’ and ‘power off’ of remote transmitter module

- Data transmission to wireless printer capability

- Simple wireless configuration and calibration

- Waterproof to IP67

How Do Massload Crane Scales Ensure Safety and Compliance?

Massload Crane Scales Ensure Safety and Compliance with:

Safety Certifications

Massload Technologies ensures the safety and compliance of its crane scales through rigorous certification processes. One key certification is the Verified Conformity Assessment Program (VCAP), which is implemented by the National Conference on Weights and Measures (NCWM). The VCAP certification guarantees that devices continue to meet stringent environmental requirements. Massload Technologies’ Quality Management System for manufacturing NTEP-approved load cells has achieved VCAP certification, ensuring that their products meet high safety and quality standards. You can view Massload’s VCAP certificate for more detailed information.

Built-in Safety Features

Overload Protection: Massload crane scales come equipped with overload protection mechanisms. These features are designed to prevent damage to the scale and ensure accurate measurements even when subjected to unexpected heavy loads.

High Accuracy and Precision:The scales use advanced sensors and undergo meticulous calibration to deliver precise measurements. This high level of accuracy is critical for maintaining safe and efficient operations, ensuring that weight readings are reliable and consistent.

What Is the Process for Calibrating and Verifying Massload Crane Scales?

Step-by-Step Process for Calibrating and Verifying Massload Crane Scales:

- Preparation: Ensure the crane scale and surrounding area are clean and free of debris. Verify that the scale is properly mounted and securely fastened.

- Warm-Up: Turn on the crane scale and allow it to warm up, usually around 15-30 minutes.

- No Load Condition: Ensure there are no loads on the crane scale.

- Zero Adjustment: Use the indicator to zero the scale, ensuring it reads zero with no load applied. This step eliminates any residual weight or tare weight from the system.

- Calibration Weights: Prepare known calibration weights

- Load Application: Carefully apply the known weights to the crane scale one at a time. Record the scale’s reading for each weight applied.

- Verification: Compare the scale’s readings to the known weights. If the readings are within the acceptable tolerance range specified, the scale is considered accurate. If not, adjustments may be needed.

- Calibration Adjustments: If the scale readings deviate from the known weights, use the scale’s calibration function to adjust the readings. This process may involve entering the correct weights into the scale’s control panel and allowing the system to recalibrate itself.

- Zero Confirmation: After calibration adjustments, remove all weights and re-zero the scale to ensure it returns to zero accurately with no load.

- Reapply Known Weights: Reapply the known weights to verify the accuracy of the adjustments. Ensure that the scale consistently provides accurate readings within the specified tolerance.

- Certification: Print the calibration certificate.

Frequency of Calibration: It’s recommended to calibrate crane scales at regular intervals, typically every year.

What Industries and Applications Can Benefit From Using Massload Crane Scales?

Most common industries and applications that can benefit from using Massload crane scales:

Construction

In construction, lifting heavy materials like steel beams and concrete blocks is a daily challenge. Massload crane scales ensure these materials are within safe load limits, preventing equipment failures and accidents.

Mining

Mining operations rely on Massload crane scales to measure ore and other materials accurately. Proper handling and transport of heavy loads are crucial, and these scales optimize the process by preventing overloading.

Oil and Gas

The oil and gas industry benefits immensely from Massload crane scales by ensuring safe and efficient lifting operations. Heavy equipment, pipes, and other materials are weighed accurately, ensuring they stay within safe limits.

Manufacturing

In manufacturing, Massload crane scales are vital for weighing raw materials and finished products. Accurate measurements ensure inventory control and quality assurance, preventing discrepancies and maintaining consistency.

Can Massload Crane Scales Withstand Harsh Industrial Environments?

Yes, Massload crane scales are engineered to withstand harsh environments.

Built with robust materials and designed for long-term use, these scales can handle extreme conditions without compromising performance.

Do Quality Crane Scales Affect Workplace Safety?

Yes, the quality of crane scales or even having crane scales at all can make a big difference in workplace safety.

Crane scales monitor weight when lifting and hoisting heavy materials, and this mitigates risks, such as overloading, material falling, equipment failure and numerous other accidents.

Moreover, quality crane scales enhance operational efficiency by offering quick and accurate readings, minimizing downtime, and reducing human error. They often meet or exceed industry safety standards, ensuring compliance with legal requirements and further enhancing safety.