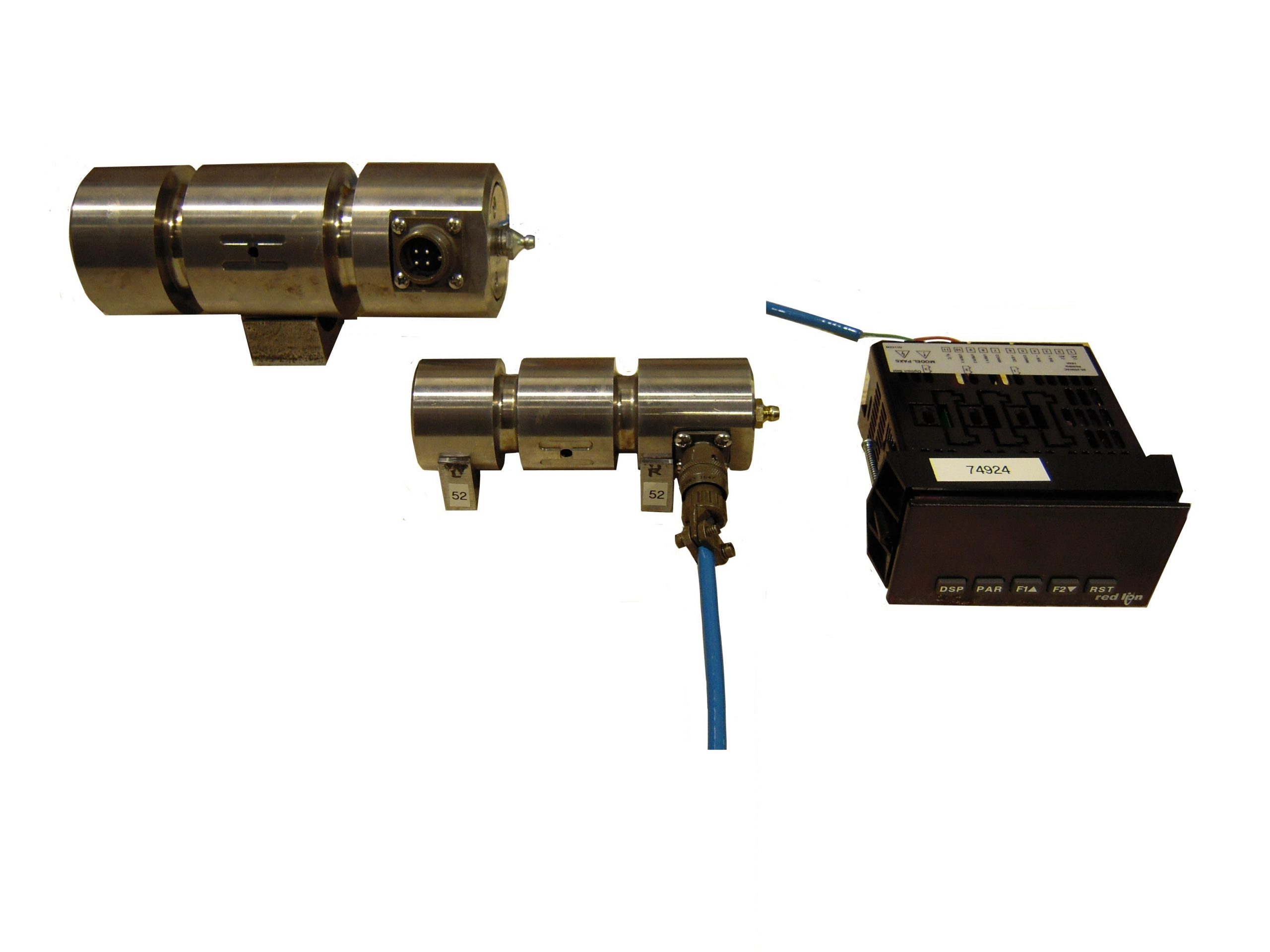

Custom Load Pin Transducers

Load pins are sometimes referred to as force sensing clevis pins, lifting pins, weight pins, force pins, or shear pins but they are all the same in that they are all strain gauge transducers that measure weight. Our load pins are custom designed to our customer’s requirements. Load pin will typically replace the sheave pin of a lifting device. Pin loading must be in one direction only or side loading will occur and reduce pin load accuracy. To this end, keeper plates are often employed to keep the force pin aligned properly.

Highlights

- Shear load pins are very versatile and used in many tension load applications

- Load pins can replace clevis pins

- Load pins minimize or eliminate crane head space

- Outputs include mV/V, 4-20mA, 0-10V, wireless

- Load pin accuracy is <1% typical; 0.1% to 0.2% may be achieved with multi-point calibration

- Load pins are susceptible to side loads so pin loading must be in one direction only

- Load pins are custom engineered and manufactured to fit the load and support arrangement

Product Details

Custom Load Pin Transducers

Meticulously crafted to meet individual customer requirements, these load pins serve as replacements for sheave pins in lifting devices, especially in the mining industry.

Primarily utilized in hoisting and tension load applications, they deliver reliable and precise measurements.

Ensuring unidirectional pin loading is crucial to avoid potential inaccuracies caused by side loading.

Frequent utilization of keeper plates maintains proper alignment, guaranteeing consistent and accurate results.

Images

PRODUCT SPECIFICATIONS

| Capacities | Available in any capacity (custom) |

|---|---|

| Typical Accuracy | <1%FS; 0.1% to 0.2%FS may be achieved with multi-point calibration |

| Safe Overload | 150% safe overload (standard but customizable) |

| Ultimate Overload | 300% (standard |

| Full Scale Output | 1 mV/V nominal typical |

| Maximum Excitation | 5 volts DC (standard, customizable to 10V) |

| Operating Temp | -40°C to +80°C (standard) |

| Compensated Temp | -10°C to +40°C (standard) |

| Sealing Standard | IP-67 (standard) protected against high pressure jets of water and short periods of emersion |

| Material | 17-4 PH Stainless Steel (standard) |

| Protective Coating | Electro-finish Stainless Steel |

| Bridge Resistance | 350 Ohm (standard but customizable) |