Tension Load Cells

What is a Tension Load Cell?

Tension load cells are measuring devices that predominantly measure tension and pull force. Openings at each end of the load cell allow for easy connection to shackles, wire rope, or other rigging. Some tension load cells are “S-type” load cells due to their shape and can be used to measure either tension or compression. Tension load cells are temperature compensated, environmentally sealed, and can be used for static and dynamic measurements. They are essential for ensuring worker and equipment safety while moving heavy loads.

Tension load cells are temperature compensated, environmentally sealed, and can be used for static and dynamic measurements. They are essential for ensuring worker and equipment safety while moving heavy loads.

Massload Tension Load Cells

All Massload’s tension load cells are made with the highest quality materials and manufactured through our specialized Quality Management System. Our in house engineering team will work with you to guarantee the development of a tension link that meets all your requirements.

Our tension links are designed using the latest technology in 3D modeling and FEA analysis.

Custom tension links are available in capacities up to, and exceeding, one million pounds and can be designed to meet industrial safety factors of up to 1000% overload protection. Millivolt output or signal conditioning utilizing a 4-20 mA output for PLC interface are available.

Contact us today and learn what Massload can do for you.

Highlights

Benefits of Tension Load Cells

- Made in Canada tension load cell for crane, winching, lifting, hanging scale applications

- Rugged design for resistance to side loading

- Capacities: 10,000 lbs, 25,000 lbs, 50,000 lbs, 75,000 lbs, 100,000 lbs, 150,000 lbs, 250,000 lbs

- Tension load accurate to o.1% FS with multi-point calibration

- Custom tension capacity available

- Light weight and portable

- Small size for reduced head space

- Output/display options include cabled, wireless, 4-20mA, 0-10V, +/- 10V, 0-5V

Product Details

Tension Load Cell Features

Openings at each end of the crane load cell allow for easy connection to shackles, wire rope, or other rigging. These hanging scales are available in capacities ranging from 10,000 lbs to over 250,000 lbs. Custom dynamometer capacity, size and safety factor is also available upon request. Each tension load cell is temperature compensated and environmentally sealed.

High-Capacity Load Cell Applications

Tension links are designed to measure the tension force experienced during heavy lifting. While they have many applications, the most popular include:

- Cranes

- Winching systems

- Towing

- Load lifting

- Hanging scale applications

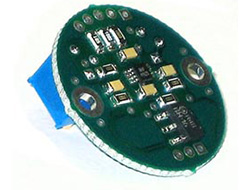

Images

PRODUCT SPECIFICATIONS

| Capacities (pounds) | 10,000 lbs, 25,000 lbs, 50,000 lbs, 100,000 lbs, 150,000 lbs, 250,000 lbs; |

|---|---|

| Accuracy | Tension load accurate to 0.1% FS with multi-point calibration |

| Safe Overload | 200% full scale safe overload |

| Ultimate Overload | 400% full scale ultimate overload |

| Full Scale Ouput | 2 mV/V nominal |

| Maximum Excitation | 10 volts DC |

| Operating Temp | -40°C to +80°C |

| Compensated Temp | -10°C to +40°C |

| Sealing Standard | IP-67 protected from dust and high pressure jets of water |

| Material | Electroless nickel coated high strength alloy steel |

| Bridge Resistance | 350 Ohm |

Please click on the following links to download or view additional information:

- Brochure Massload Tension Link Tech Sheet

Testimonials

Frequently Asked Questions

How Do Tension Load Cells Work?

Tension load cells use a four-step measurement process:

- When tensile force is applied, the load cell body deforms slightly

- Strain gauges attached to the body detect this deformation, causing their electrical resistance to change

- A Wheatstone bridge circuit converts the resistance change into a measurable electrical signal

- Electronic equipment interprets this signal to determine the precise tensile force being applied

What Is Strain Gauge Technology and Why Is It Used in Tension Load Cells?

Strain gauge technology is the primary measurement method used in tension load cells. Strain gauges are sensors whose electrical resistance changes proportionally when stretched or compressed.

When mounted on the load cell body, they deform along with it under tension, creating a resistance change that directly correlates to the applied force. This technology provides highly accurate, reliable force measurements essential for safety-critical lifting and weighing applications.

Why Are Some Tension Load Cells Called “S-Type” and What’s the Advantage?

Not all tension load cells are S-type. ‘S-type’ refers to specific load cells named for their characteristic S-shaped body design. This shape helps align the mounting points along the central axis, which is particularly beneficial in suspended applications like crane scales and overhead lifting.

The geometry ensures proper load distribution and accurate measurements while minimizing side-loading effects that could compromise accuracy or damage the load cell. They are a popular choice for both tension and compression use cases.

What Are Tension Load Cells Used For?

Tension load cells serve five primary application categories:

- Hoisting and Lifting Operations: Ensuring cranes and hoists don’t overload by accurately measuring lifted weight

- Material Handling: Monitoring and controlling tension in web, wire, or cable during manufacturing

- Structural Testing: Measuring the tensile strength of materials and structures

- Crane Scales: Providing accurate weight measurements in suspended weighing applications

- Testing Equipment: Measuring tensile forces applied to samples in laboratory and quality control settings

- Vehicle Recovery: Monitoring towing forces to ensure safe and effective vehicle recovery operations