Farm Truck Scales

Highlights

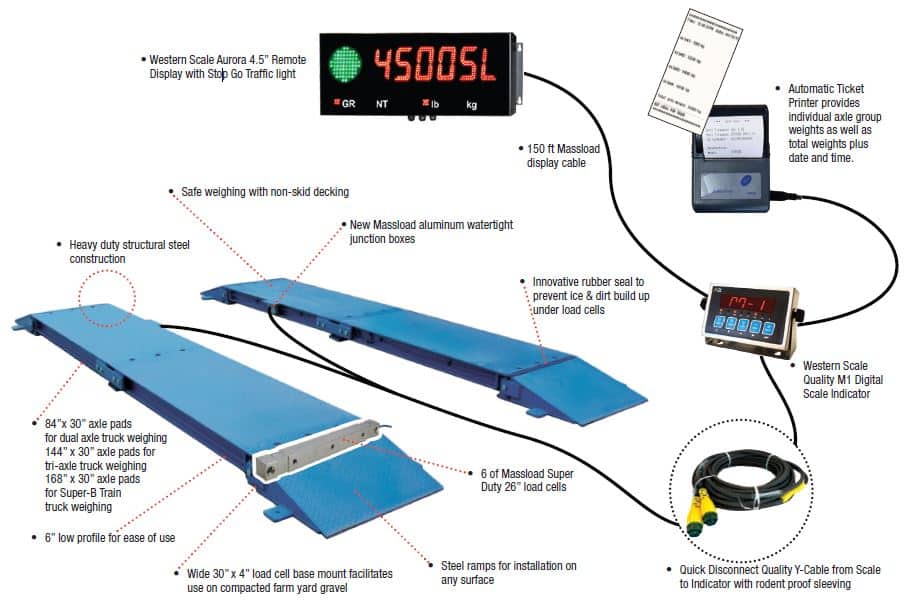

- Proven Durability Under the Toughest Conditions

- Fully Made in Canada

- 84″ axle scale: 30,000lbs/pad (60,000lbs/axle grouping)

- 144″ axle scale: 40,000lbs/pad (80,000lbs/axle grouping)

- 168″ axle scale: 30,000lbs/pad (80,000lbs/axle grouping)

- Gross vehicle weight (Super-B) accurate to within 1% FS

- Axle weight accurate to within 0.25% FS

- Calibrated with fully traceable certified weights

- Axle scales can be used on compacted yard gravel

- 6″ low profile for ease of use

- 2″ clearance under platforms

- Forklift portable for use in multiple locations

- 10 year warranty on axle scale platform

- 5 year warranty on our Made in Canada truck scale load cells

- 2 year warranty on electronics, printer & cables

Product Details

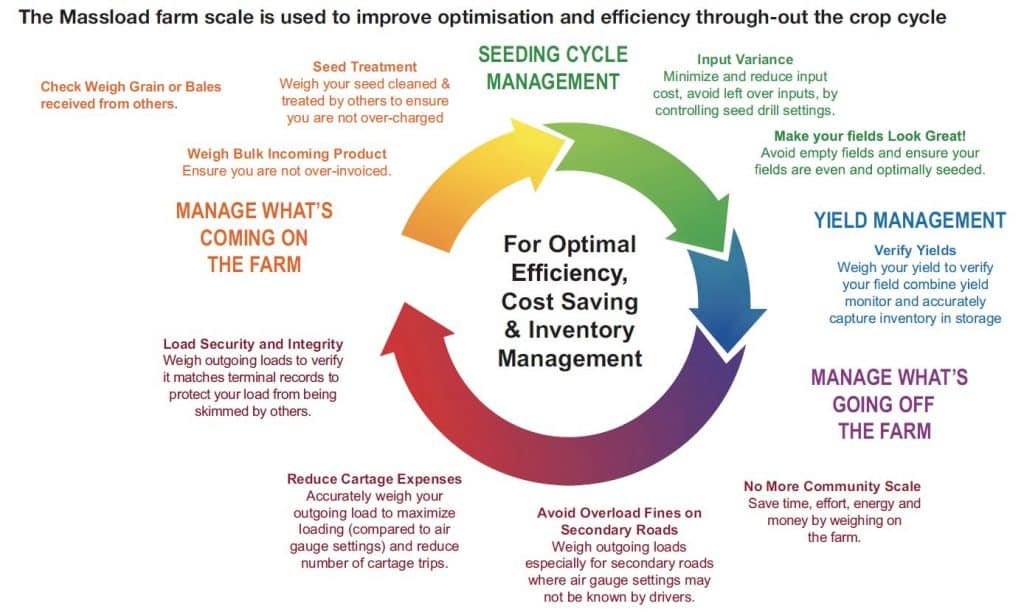

Why Use the Massload Farm Truck Scale™?

Do you experience any of the following challenges?

– Fed up with wasting time, effort, energy and money driving to the community scale

– Feeling anxious about being caught overloaded

– Worried by the prospect of time, effort and energy to deal with overload fines

– Having doubts about whether all your product is getting to the terminal and being weighed

– Want to be sure you are getting all the inputs that you’re invoiced for

– Concerned you are missing out by under or over-applying inputs

– Uncertain whether your combine yield monitor is accurate

– Frustrated with manual tracking of all your product flow

Join the hundreds of crop farmers across Canada who already reap the benefits of the proven Massload Farm Truck Scale:

– Say goodbye to driving to the community scale

– Prevent the unwanted loss of hard-earned money from overload fines

– Easily track, monitor and control input variables to improve yield

– No more worries about running out of seed/fertilizer due to over application

– Feel confident that you are getting what you pay for

– Save time, reduce effort, and increase your money

– Have peace of mind with a farm scale right in your yard

– Capture product flow with Data Management software

Benefits of Massload’s Farm Truck Scales

The Massload Farm Scale™ is built with rugged and reliable construction to provide all weather on-farm weighing of large super-B train trucks and Ag equipment.

Our Farm Scale is designed for easy installation and use directly on farm yard compacted gravel or on a concrete pad.

You can weigh everything from seeding-to-shipping and provide real-time data management with truck-in/truck out capability using Massload’s Advanced Weigh Scale Software.

We have a solution for every need, ranging from starter systems for infrequent use, to heavy duty continuous-use systems for super-Bs with real-time data management software. We also offer In-Ground Weigh-in-Motion systems for touch free operation.

With an equipment life of 20 years or more, cost per year becomes a small investment with huge value to operations over time.

Competitive lease-to-own options available to minimise impact on cashflow

How Farm Truck Scales Work

Prior to weighing, the remote display stop-go traffic light displays green indicating ready to proceed onto scale.

When the first truck axle is driven onto the axle scale, the remote display stop-go traffic light turns red, signaling driver to stop.

When the axle weight is captured, the axle number is displayed (e.g., A1) followed by the axle weight. The A1 axle weight is also printed out.

The traffic light then turns green indicating driver to proceed driving next axle group onto the scale.

When next axle group is on the scale, the signal light turns red for driver to stop. This process is repeated for all axle groups.

When last weigh is complete and the truck is driven off the scale, after a period of 15 seconds, the total weight is displayed flashing for several seconds. The printed weight ticket is also completed. The traffic light reverts to green and the system is ready for the next truck.

Each weight ticket can be removed after printing. Alternatively, they can be left as subsequent vehicles are weighed and the roll of weight tickets can then be removed.

Massload Farm Truck Scale Baseline Configuration

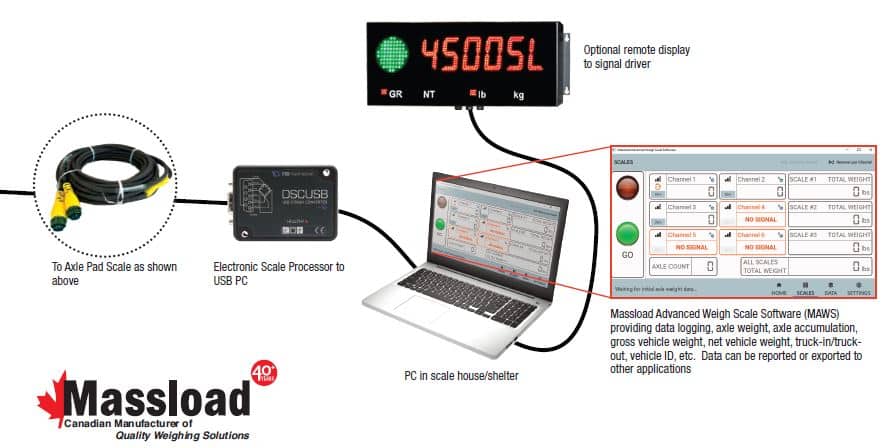

Data Management Software Configuration for Farm Truck Scales

Wireless Option

This configuration does not use an external remote display. Instead, a mobile PC tablet is in the cab with the driver.

The app (Massload Advanced Weigh Scale Software MAWS) controls the operation in a similar manner to above. The app has a stop-go traffic light which directs the driver as with the remote display configuration.

All weigh data is captured and logged in the app together with truck ID and other information.

Wired Option

In this configuration, the PC is in the scale house and is connected by wire to the scale via the Electronic Scale Processor. The app controls the operation as per above. A remote display can be connected to the PC and the app will control the display as in the hardware option. Alternatively, a scale operator can communicate to the driver via cell phone instructions based on the stop-go signal light on the app.

For more information go to Documents and download the brochure. Contact Massload today via the Request a Quote form or call and speak to our technical sales on 1-800-667-3825.

Images

Videos

PRODUCT SPECIFICATIONS

| Rated Capacity (pounds) | 84″ axle scale: 30,000 lbs/pad (60,000 lbs/axle grouping) |

|---|---|

| Load Cells | ML 1100-25K (Output: 2mV/V) |

| Accuracy | Gross Vehicle Weight (Super-B Train) independently tested to accuracy of 1% FS nominal |

| Overload Capacity | 150% full scale safe overload |

| Temperature Range | -40ºC to +80ºC (operating) |

| Graduation | 20 lbs (30,000 lbs and 40,000 lbs capacity). Calibration in kg is available. |

| Material | Load Cells: Made by Massload in Canada with quality alloy steel from USA or Europe. |

| Fatigue Limit | Infinite cycles per day (axle loads) |

| Ground Requirements | The ground must be flat and level, fully supporting loads and with proper drainage |

| Dimensions | Platform Weighing surface: |

| Sealing Standard | IP-66: totally protected from dust; protected from strong jets of water |

| Power | Axle scales are powered by digital load cell indicator |

Please click on the following links to download or view additional information:

- Brochure Massload Technologies Farm Truck Scales

- Brochure Truck Axle Pad Scale Auto Weighing By Massload Technologies

- Brochure "Crop farmers demand accurate truckload weighing systems," as Published in Harvest 2012 Nipawin Sun

- Brochure 30" & 84" Wiring & box options

- Brochure 144 Wiring & box options

- Brochure 144 Wiring & box options

- Brochure Axle weighing and errors

- Manual Stop Light Axle Adding

- Manual 30 x 30 Heavy Duty Pad