Wireless Load Cells, Load Pins, Tension Links, and Load Shackles

Welcome to the cutting edge of industrial weighing. Our wireless load cells, load pins, tension links, and load shackles are the result of years of research and technical expertise to give you the equipment you need to weigh with ease and accuracy.

Traditional weighing systems with cables and limited flexibility are a hindrance to productivity and accuracy. That’s where our wireless scales come in. By removing the constraints of wired systems our load cells give you ultimate flexibility to integrate into any industrial application from vehicle scales to heavy machinery.

But it’s not just about cutting cords. Our wireless scales still give precision and reliability in lifting and weighing operations just like the wired version.

Our goal is to give industries that can benefit largely from wireless ways of measuring their daily applications. Whether it’s monitoring tension forces in crane operations or measuring loads on offshore platforms our solutions give safety, efficiency and peace of mind to businesses across all industries.

With Massload Technologies, you’re not just investing in cutting-edge technology – you’re investing in the future of your operations.

WIRELESS LOAD SHACKLES

Support local manufacture with Massload's rugged and reliable industrial grade ML-724 2.4 Ghz Wireless Tension Link model ranges from 10,000 lbs to 250,000 lbs, made with the highest quality materials and manufactured and calibrated in-house through our VCAP certified Quality Management System. Common applications include load lifting, boat lifting, towing and line tension measurement.

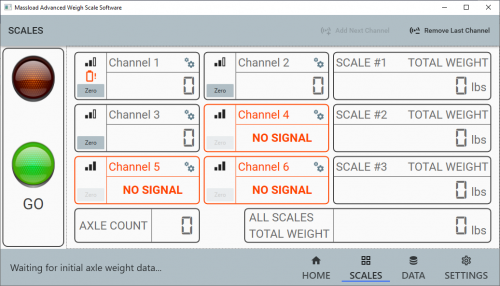

MASSLOAD .NET ADVANCED WEIGH SCALE SOFTWARE (MAWS)

Support local with Massload's .NET Advanced Weigh Scale Software for wireless weighing. Ideal for applications including data logging, axle weighing, multi-axle weighing, multi-scale weighing for tension link, platform and tank weighing, load out weighing, and truck in truck out operation.

WIRELESS TENSION LINK

Support local manufacture with Massload's rugged and reliable industrial grade ML-724 2.4 Ghz Wireless Tension Link model ranges from 10,000 lbs to 250,000 lbs, made with the highest quality materials and manufactured and calibrated in-house through our VCAP certified Quality Management System. Common applications include load lifting, boat lifting, towing and line tension measurement.

WL-T24-HS HAND HELD DIGITAL LOAD CELL INDICATOR

Massload 2.4Ghz Wireless hand held single channel load cell weight indicator with up to 2600ft (800m) range.

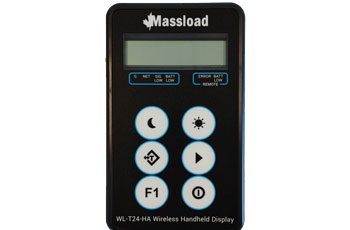

WL-T24-HA HAND HELD MULTI-CHANNEL DIGITAL LOAD CELL INDICATOR

Massload 2.4Ghz Wireless hand held load cell weight indicator for up to 12 channels with 2600ft (800m) range.

WL-T24-ACM WIRELESS LOAD CELL TRANSMITTER (IP67 ENCLOSURE)

Mantracourt 2.4Ghz Wireless Load Cell Transmitter with up to 2600ft (800m) range and long battery life. Use with any scale or load cell for cable-less weight sensing and data collection.

WL-T24-BSu USB WIRELESS RECEIVER

Mantracourt 2.4Ghz Wireless base station receiver connects to USB port with free software to display up to 100 channels.

WL-T24-AO1i WIRELESS ANALOGUE OUTPUT

Mantracourt T24-AO1i wireless receiver with analogue output connects with the T24-ACM wireless load cell transmitter to provide 0-20mA, 4-20mA, 0-10V, 0-5V, +/-10V +/-5V output options to the PLC controller.

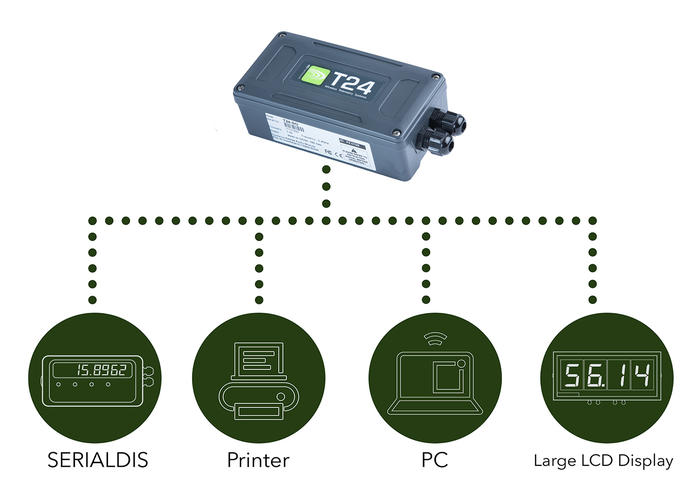

WL-T24-SO WIRELESS LOAD CELL SERIAL OUTPUT GATEWAY

Mantracourt T24-SO wireless receiver provides serial ASCII output to serial display, printer, PC and LCD displays.

WL-T24-LOG100 LOAD CELL DATA LOGGING SOFTWARE

Mantracourt T24 Log 100 software provides easy-to-use data logging and weight display for up to 100 channels.

What are Wireless Load Cells?

Wireless load cells are used in many applications but the two most common are in hoisting and in vehicle scales. They get rid of the cables and give you more flexibility and convenience in weighing.

How Does a Wireless Load Cell Work?

Wireless load cells give you insights into force and weight measurement across many applications. Here’s a breakdown:

- Wireless Transmission: Converts force or weight into electrical signals and transmit data wirelessly to a collection system.

- Operation Overview: These load cells work on strain gauge technology to give you precise and reliable weight measurement.

- Measuring Weight: Gives you real-time weight measurement by sensing strain.

What are Wireless Tension Links?

A wireless tension link, also known as a wireless dynamometer, is a device used to measure tension or force without physical connections or wires.

How Does a Wireless Tension Link Work?

A wireless tension link gives you real-time monitoring and measurement of tension loads. Here’s how a wireless tension link works:

- Load Sensing: The core component of a wireless tension link is a load sensing element, usually a strain gauge or load cell. This component deforms slightly when subjected to force or tension. This deformation is measured and converted into an electrical signal proportional to the applied force.

- Signal Processing: The electrical signal generated by the load-sensing element is then processed by onboard electronics. This processing may involve amplifying the signal, filtering out noise, and converting it into a digital format for transmission.

- Wireless Transmission: Once the electrical signal is processed, it is transmitted wirelessly to a receiver unit. This transmission can occur through various wireless communication protocols. At Massload, we use license-free 2.4 GHz wireless technology on the ISM band in different form factors such as enclosures and battery life depending on the best fit for each application.

- Wireless Receiver Unit: It receives the wirelessly transmitted signal from the tension link and decodes it back into a readable format, usually displaying the measured tension or force in real time. The wireless receiver unit comes in multiple options such as hand-held LCD readout displays, base station connected to a personal computer running Massload MAWS scale software or other software, 4-20mA output direct to a PLC, or serial output connected to a display device.

- Power Source: Wireless tension links are powered either by batteries of various sizes selected for battery life requirements, or by rechargeable batteries maintained by solar power or induction charging, or by regular utility power. The choice of power source depends on factors like the intended usage duration and environmental considerations.

What are Wireless Load Shackles?

Wireless load shackles are devices used to measure tensile loads in many lifting applications. They use load pins to convert force into electrical signals to an integrated wireless transmitter.

How Does a Wireless Load Shackle Work?

A wireless load shackle gives you real-time monitoring of tensile loads, making lifting safer and more efficient. Here’s a breakdown:

- Functionality: Wireless load shackles measure weight or load in many industrial applications. Unlike the traditional wired version which requires physical connections for data transmission, the wireless version uses advanced technology to transmit data wirelessly, giving you more flexibility and convenience.

- Operation Overview: At the heart of a wireless load shackle are sophisticated sensors that can detect load changes with great precision.

- Measuring Weight: When a load is applied, the sensors in the wireless load shackle detect force or tension.

This data is then converted into electrical signals, which are transmitted wirelessly to a receiver or data collection system.

Software: Massload’s .NET Advanced Weigh Scale (MAWS)

Massload’s Advanced Weigh Scale software, also known as MAWS, is our latest .NET software for multi-scale wireless weighing and vehicle weighing. The vehicle weigh options include multiple wheel or axle scales, axle accumulation and totalisation, truck in -truck out, gross and net vehicle weight, vehicle ID capture, and general data capture and management.

Suitable for many applications including data logging, axle weighing, multi-axle weighing, tension link weighing, platform and tank weighing, load-out weighing, and truck-in truck-out.

Indicators or Readouts for Wireless Scales

Many load cell applications need indicator devices to display the measurement while still operating safely and efficiently.

At Massload we work with a full range of indicators for wireless scales to make your weighing applications more efficient and convenient.

Our range includes products to suit many needs, so you can get accurate weight measurements without the restrictions of traditional wired systems.

From single-channel load cell indicators like the WL-T24-HS Handheld Digital Load Cell Indicator with a range of up to 2600ft (800m) to multi-channel solutions like the WL-T24-HA Hand Held Multi-Channel Digital Load Cell Indicator that can handle up to 12 channels, our products give you accurate weight measurement.

Cut the Cord: Revolutionize Your Wireless Weighing Operations with Massload

Experience the latest in industrial weighing technology with Massload’s wireless load cells, load pins, tension links, and load shackles. Say goodbye to the restrictions of traditional wired systems and hello to freedom and convenience.

Invest in your future operations with Massload Technologies today. Contact us and let us help you find the perfect weighing solution for your needs!

Frequently Asked Questions

What does a load cell transmitter do?

A load cell transmitter takes the electrical signals from load cells which measure changes in force or weight.

The transmitter amplifies, conditions and converts these signals into a format that can be sent over a wireless communication channel to a display device or data collection system.

How does a load cell work?

Load cells work on the principle of strain gauge technology. When force is applied to a load cell it deforms slightly and the electrical resistance or voltage output changes. This change is directly proportional to the applied force so load cells can measure weight or force. The electrical signals from the load cell are then processed and interpreted by associated electronics to give real-time weight measurements.

How long does a load cell last?

The lifespan of a load cell is application dependent, environment dependent and usage dependent and maintenance dependent. However high quality load cells like the ones designed and manufactured by Massload will last for many decades if properly cared for and maintained. Regular calibration, inspection for damage or wear and following the manufacturer’s guidelines for installation and usage will help extend the life of load cells.

What is the difference between a force sensor and a load cell?

Force sensors and load cells both measure force or weight but are different in their applications and construction. A force sensor is a general term for any device that measures force including load cells.

Load cells are a type of force sensor that use strain gauge technology to measure force or weight. Load cells are often designed to measure static or dynamic loads while force sensors may be designed for specific force ranges or applications.