Material force testing is the process that ensures safety and efficiency for industries worldwide.

Measuring weight is key to testing whether a material will handle its function well when dealing with heavy cargo.

There are all kinds of tests, and the most compatible load cell must be used for each one.

Keep reading to discover what tests are generally used, their main benefits, why custom load cells are beneficial, and how to select or design the best load cell for your application.

What is Material Force Testing?

Material testing is meticulously examining materials to uncover their intrinsic properties and performance under various conditions.

Engineers can analyze properties like strength, elasticity, hardness, and resistance to wear and fatigue when subjecting materials to different stresses and environmental conditions, such as:

- Tensile Forces: Assessing how materials stretch under tension.

- Compressive Load: Evaluating how materials react to being compressed.

- High Temperatures: Observing changes in material properties under heat.

This data is essential for selecting the right materials for specific applications in a wide range of industries.

Types of Material Testing that Use Load Cells

Peel Testing

Peel Testing measures the adhesive strength between two bonded materials. In this test, one layer is peeled away from the other at a controlled angle and speed. The force required to peel the material is measured, which helps determine the adhesive’s quality and suitability for various applications. Custom load cells designed for peel testing ensure precise force measurement and consistency.

Tensile Testing

Involves pulling a material until it breaks to determine its tensile strength, yield strength, elongation, and modulus of elasticity. The resulting stress-strain curve provides insights into the material’s mechanical properties. Custom load cells for tensile testing must accurately measure high-tensile forces and capture detailed data throughout the test.

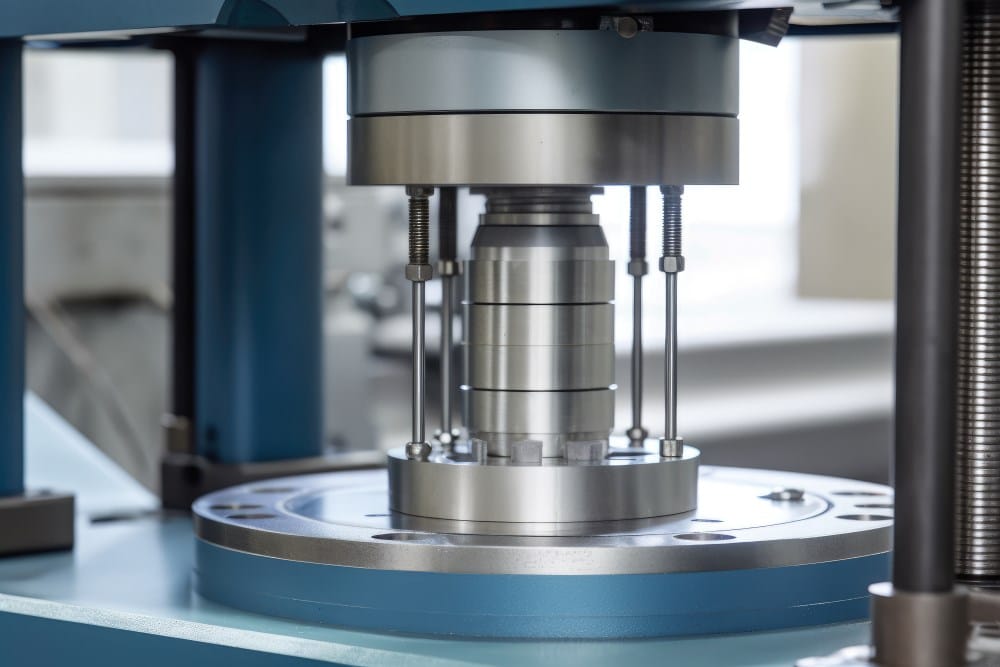

Compression Testing

Compression Testing assesses how materials behave under compressive forces. The material is placed between two plates, and a compressive load is applied until it deforms or fails.

Load cells ensure accurate and consistent readings of compressive strength, stiffness, and deformation characteristics. This helps in determining the load-bearing capacity of materials.

Shear Testing

Shear Testing measures the material’s ability to resist shear forces, which cause internal sliding between material planes.

Custom load cells provide precise data on the material’s ability to resist internal sliding forces, ensuring accurate shear strength assessment.

Fatigue Testing

Fatigue Testing evaluates the material’s durability under repeated or fluctuating loads over time.

Load cells enable detailed analysis of the material’s fatigue life and resistance to crack formation, which is crucial for predicting long-term durability under cyclic loads.

Creep Testing

Creep Testing evaluates how materials deform under a constant load over an extended period, especially at high temperatures. Load cells help determine the material’s creep resistance and long-term stability, particularly at high temperatures.

The Benefits of Using Custom Load Cells in Material Force Testing

Custom load cells offer several significant benefits in material testing across various industries.

Here Are the Key Advantages:

- Enhanced Accuracy and Precision: Custom load cell design is made to meet specific testing requirements, ensuring high levels of accuracy and precision.

- Adaptability to Specific Testing Conditions: They can be tailored to fit unique shapes, sizes, and mounting configurations, making them ideal for specialized testing environments that standard load cells cannot accommodate.

- Improved Durability and Longevity: Engineered to withstand specific environmental conditions, enhancing their durability and lifespan.

- Versatility Across Different Test Types: They can be optimized for various types of material testing, including tensile, compressive, shear, fatigue, and impact tests, providing comprehensive data for multiple testing scenarios.

- Customization for Specific Load Ranges: Custom load cells can be designed to accurately measure a wide range of forces, from very small loads to extremely high forces, ensuring that they meet the specific needs of different testing applications.

- Integration with Existing Systems: They can be customized to seamlessly integrate with existing testing setups and instrumentation, reducing the need for extensive modifications and ensuring smooth operation.

- Cost-Effectiveness in Long-Term Use: Despite the higher initial investment, custom load cells often prove to be cost-effective in the long run due to their enhanced durability, reliability, and reduced need for frequent replacements or repairs.

- Expert Technical Support and Service: Custom load cell providers typically offer specialized support and services, including expert consultation, custom design assistance, and ongoing technical support, ensuring optimal performance and user satisfaction.

How to Choose a Custom Load Cell for Material Testing

Here are the key steps and considerations to guide you in selecting the appropriate load cell:

1. Determine the Type of Test

Identify the specific type of material force test you will be conducting, such as tensile, compression, shear, fatigue, or impact testing. Different tests may require different types of load cells, such as tension load cells for tensile tests or compression load cells for compressive tests.

2. Load Capacity

Select a load cell with a capacity that matches or slightly exceeds the maximum load you expect to measure. Using a load cell with the appropriate capacity range ensures accuracy and prevents damage to the load cell. For example, if you expect to measure loads up to 500 kg, choose a load cell with a capacity of around 600-700 kg.

3. Accuracy and Precision

Consider the required accuracy and precision for your application. Look for load cells with high accuracy specifications, typically represented by their percentage of full scale. For material testing, high-accuracy load cells (with an accuracy of ±0.1% or better) are often necessary to ensure reliable data.

4. Environmental Conditions

Assess the environmental conditions in which the load cell will operate. Factors such as temperature, humidity, and exposure to corrosive materials can affect load cell performance. Choose a load cell with appropriate environmental protection ratings (e.g., IP67 or higher for harsh environments).

5. Form Factor and Size

Ensure the load cell fits the physical constraints of your testing setup. Consider the dimensions, mounting options, and form factor of the load cell to ensure it integrates smoothly with your existing equipment and fixtures.

6. Signal Output and Compatibility

Check the signal output type of the load cell and ensure it is compatible with your data acquisition system or testing equipment. Common output signals include analog (mV/V) and digital (RS232, RS485) outputs. Ensure your system can read and process the load cell’s output.

7. Calibration and Certification

Verify that the load cell can be calibrated to your required standards and check if it comes with calibration certificates. Regular calibration is essential for maintaining measurement accuracy over time.

8. Budget and Cost-Effectiveness

While it’s essential to select a load cell that meets all technical requirements, also consider your budget. Evaluate the cost-effectiveness of the load cell, factoring in not just the initial purchase price but also long-term maintenance and calibration costs.

9. Manufacturer Reputation and Support

Choose load cells from reputable manufacturers known for quality and reliability. Consider the availability, efficiency, and quality of technical support, warranty, and after-sales service, which can be crucial for troubleshooting and maintenance.

Get to know what Massload’s clients say about our support team here.

How Massload Technologies Builds Custom Load Cells

At Massload Technologies, we understand that every material force testing application has unique requirements. Our custom load cells are designed and manufactured to meet these needs, ensuring precision and reliability.

Here’s how we build custom load cells tailored to your requirements:

Define Your Requirements

We start by working closely with you to define clearly the specific requirements of your material testing application. This includes determining the load range, accuracy, environmental conditions, and form factor needed for your custom load cell.

Select Materials

We choose high-quality materials that can withstand the expected load and environmental conditions. Common materials we use include stainless steel and aluminum for their strength and durability.

Design the Load Cell

Our engineers utilize advanced computer-aided design (CAD) software and FMEA (Failure mode and effects analysis) reports to create detailed designs of your custom load cell. The design process ensures the load cell incorporates the necessary strain gauges, mounting points, and wiring channels for optimal performance.

Strain Gauge Placement

We carefully place, and bond strain gauges on the load cell in locations where they can accurately measure the deformation caused by applied loads.

Wiring and Signal Conditioning

Our team first connects gauges into a Wheatstone bridge circuit that amplifies and converts the strain gauge signals into readable outputs.

Calibration, Testing, and Validation

We calibrate the custom load cell to ensure that it provides accurate measurements corresponding to the applied loads.

Massload’s Custom Load Test Fixtures

Massload also makes an extra effort in manufacturing custom load test fixtures in order to accurately test the load cell resistance and capability to validate the performance of the custom load cell.

Ready to Choose the Perfect Load Cell?

Choosing the right load cell for your material force testing needs is like picking the perfect tool for a delicate craft.

Whether you’re selecting a commercially available load cell or building a custom one with Massload Technologies, understanding the specific needs of your material force testing application is essential.

Let Massload’s 40+ years of experience help you select or custom-build the ideal load cell for your specific needs, ensuring accurate and reliable results for your testing processes.

Contact us now and take the first step towards safer, more efficient material force testing!