July 24, 2023

July 24, 2023

Industrial operations need to be able to read and record the weight and content of their applications and understand mechanical force. Load cells are transducers that convert mechanical force into simple digital values. There are many types of load cells, each with their own benefits for the application. Massload Technologies is an industrial manufacturer of load cells, we offer shear beam, single beam, double beam, S-type, single point bending beam, pancake, column, donut ring, button and canister types.

Our guide can help you understand the different types of load cells, choose the right one for your application, and how to maintain them for accuracy and longevity.

Why Load Cells are Used in Industrial Applications

Load cells measure high force and are used in industrial applications where weight readings are critical. Many electronic weighing systems use load cells because of the benefits, which include:

- High Accuracy: Load cells provide precise force measurement, a big plus in industries that require accuracy like manufacturing, transportation and construction.

- Wide Range of Applications: From low capacity sensors used in retail to high capacity solutions in heavy industry, load cells can be used in many applications.

- Reliability: Load cells are tough and provide reliable performance over time, even in harsh industrial environments.

Load Cell Types

Load cells come in different designs, measurement methods, and application suitability. Here’s an overview of the most common types:

Shear Beam Load Cells

Shear beams measure force by a strain gauge placed on the surface of the load cell. When force is applied, the strain gauge deforms by bending the load cell. Common in platform scales and silo weighing, shear beams are suitable for high-capacity and stable measurements.

Single Beam Load Cells

A type of shear beam load cell, single beams measure shear distortion from a single point, suitable for low capacity applications like bench scales and packing lines.

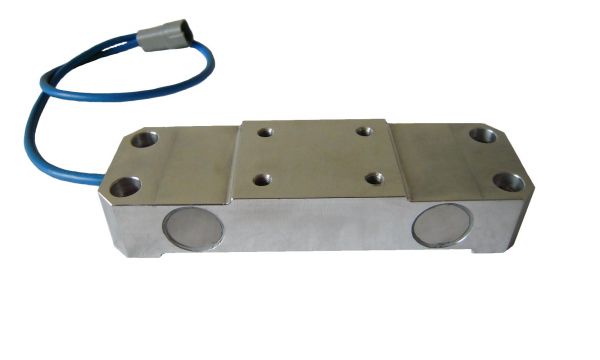

Double Beam Load Cells

Two points of shear measurement, double beams are suitable for harsh environments that require higher reliability and stability. Commonly used in tank weighing, silo monitoring, and large container weighing.

S-Type Load Cells

S-shape load cells accurately measure small forces and are suitable for tension applications and crane scales. Used in applications that require dual measurement capabilities like tensile strength testing.

Single-Point Bending Beam Load Cells

Fixed at one end with the load applied to the other, these load cells provide high accuracy for single-point weighing and are used in food processing and packaging.

Pancake Load Cells

Flat shape load cells, they measure both tension and compression. Stable and precise they are suitable for high stress applications like dynamometers and fatigue testing in aerospace and automotive industries.

Column Load Cells

Spring element designed for axial loading, column load cells are used for heavy duty applications like bridge monitoring and construction. Durable for large structural loads.

Donut Ring Load Cells

Low profile load cells with through hole, suitable for applications where the load structure needs to pass through the sensor like bolt force measurement.

Button Load Cells

Compact and space-efficient button load cells are used in spatially constrained applications like medical device testing.

Canister Load Cells

Similar to column load cells, canister load cells can handle high-capacity loads with high accuracy and durability in harsh environments like mining and shipbuilding.

Choosing the Right Type of Load Cell

When choosing a load cell, you need to consider specific requirements and environmental factors. Here’s a checklist to help you:

- Capacity: Can the load cell handle your maximum weight or force requirement? Single-point load cells are used for low capacity, and column load cells are used for heavy-duty applications.

- Accuracy Requirements: For high-precision applications (e.g. medical or electronics) consider button or S-type load cells.

- Environmental Conditions: Harsh environments like construction and mining require durable load cells that can withstand extreme conditions without compromising accuracy.

- Load Type: Do you need tension, compression or both? Pancake and canister load cells can measure both.

- Size Constraints: In spatially constrained applications, button or donut ring load cells are the way to go.

- Mounting Requirements: Applications with specific mounting requirements may need a single point or S-type.

- Budget: It’s not just about choosing the most rugged or high-capacity load cell; it’s about getting the best value for your needs. Think about factors like customization, accuracy, and your specific application. By balancing cost with performance, you can find a load cell that fits both your budget and your goals.

This checklist will help you ensure your chosen load cell meets your application’s specific needs.

Tips for Accuracy and Longevity

Maintenance is key to maintaining accuracy and extending the life of your load cells. Here are a few:

- Calibration: Calibrate every 6-12 months to prevent accuracy drift, especially if the load cell is used frequently or heavily.

- Physical Inspection: Check for wear, corrosion, or damage, especially if the load cell is used in harsh environments.

- Check Connections: Check wiring and connectors to ensure they are intact and secure to prevent signal interference.

- Environmental Protection: In outdoor or extreme conditions, either use load cells that are designed for these conditions or use enclosures or weatherproofing to prevent degradation from moisture, dust, or chemicals.

- Follow Manufacturer Guidelines: Manufacturer recommendations are to maximize the life and accuracy of specific load cell models.

Proper maintenance will reduce replacements and ensure reliable and accurate performance over time.

How Massload Technologies Can Help You Choose the Right Load Cell

At Massload Technologies, we know choosing the right load cell can be overwhelming. With 40+ years of experience in the industrial weighing industry, we can help you navigate the many load cell options. Our team will find the right one for you for small applications or heavy-duty industrial systems.

- Expert Guidance: Our engineers will work with you to understand your needs and recommend the right load cell for your application, environment, and performance.

- Custom Solutions: We offer custom load cell solutions to meet your needs. Capacity, accuracy or physical size, we will tailor the load cell to your exact application.

- Total Support: From consultation to maintenance, Massload Technologies has got you covered. Our technicians are available for troubleshooting, repair, and calibration services to keep your load cell system running smoothly.

- Ongoing Support: We believe in long-term relationships with our clients; we offer expert advice and service throughout the life of your load cell equipment. Need periodic recalibration or adjustments to meet changing requirements? We’re here to help.

- Quality and Reliability: At Massload Technologies, we take pride in designing and manufacturing most of our own load cells to ensure top-notch quality and reliability. Built to handle tough environments, our load cells are made to perform for years. When we do source components, we carefully choose trusted manufacturers who share our commitment to excellence.

Choose Massload Technologies for your load cell needs. With a focus on quality and customer satisfaction, we’re here to provide the best solutions for your applications.

Get the Right Load Cell for Your Application with Massload Technologies

Choosing the right load cell type, capacity, and features is critical for accuracy and efficiency in any application. With so many options to choose from, expert advice can make all the difference. At Massload Technologies, we will guide you through the selection process to find a load cell that fits your exact needs.

Get in touch with us today to ask about load cell capabilities or request a quote for a solution for your force measurement requirements.