April 10, 2024

April 10, 2024

Load cells are the first component to understand in the field of industrial weighing, and in this guide, we will walk you through the different types of load cells (strain gauge, pneumatic, hydraulic, capacitance) and their many industrial applications.

From the basics to the practicalities of choosing the right load cell for you, let’s dive into the world of load cells.

What Are Load Cells?

A load cell is a transducer that converts force into electrical output. Among the many different varieties, strain gauge load cells are the most common force sensor for their accuracy and reliability.

In situations where safety and hygiene are critical, pneumatic load cells are preferred, while hydraulic load cells are a solution for remote locations where a power supply is not available.

Massload load cells have an accuracy range of 0.1% FS* to 0.2% FS* when calibrated through a multi-point system.

*FS or Full Scale is the term used to describe the maximum range or capacity of a device. For example, if a load cell has a full scale of 1000 kg, the full scale (FS) is 1000 kg.

How Do They Work?

A load cell converts mechanical force into digital readings that you can see and store. The mechanics of it all vary depending on the type you choose—hydraulic, pneumatic, or strain gauge load cells.

Of these, strain gauge load sensors are used in weighing applications in industries from industrial to medical to retail.

They have strain gauges that detect voltage changes when force is applied and convert that into digital weight readings.

What’s the Difference Between Tension and Compression Load Cells?

Tension and compression load cells are two distinct types that measure force in different directions.

Tension Load Cells

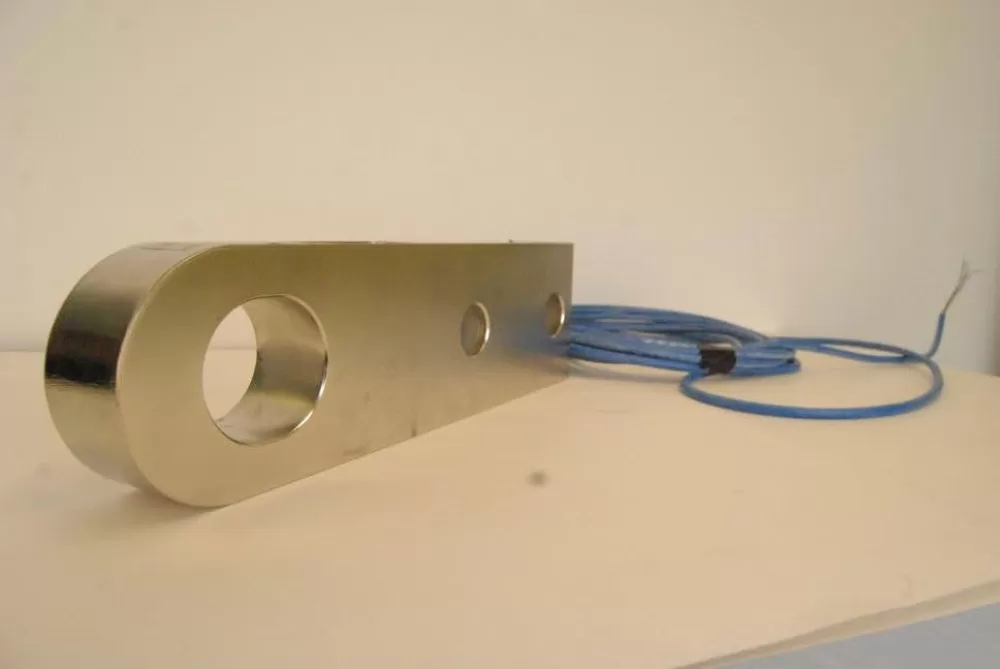

Tension load cells are designed to measure forces pulling or stretching. They have holes on each end to attach the load to be measured.

These load cells are for when the force is in tension, to measure tensile forces.

When to Use

Use tension load cells when you need to measure forces pulling or stretching, like crane, hoisting and lifting. They are for applications where the force is tensile.

Compression Load Cells

Compression load cells are designed to measure forces pushing or compressing together. They have flat surfaces or mounting plates to bear the measured weight or pressure.

When to Use

Use compression load cells when measuring forces that are pushing or compressing together, like weighing heavy loads or monitoring pressure in industrial processes.

Tension load cells are for tensile forces, and compression load cells are for compressive forces. Choosing the right one based on the direction of force in your application will give you accurate and reliable force measurement.

What are the Different Types of Load Cells?

The Common Types of These Sensors Are:

- Strain gauge

- Pneumatic

- Hydraulic

- Capacitance

Strain Gauge Load Cells

A strain gauge load cell is a transducer that changes its electrical resistance when stressed or strained.

This change in resistance is directly proportional to the stress or strain applied to the cell, making calibration easy for precise measurement.

Because of the linear electrical resistance, the strain gauge can be converted to force if required.

Pneumatic Load Cells

A pneumatic load cell works by using air pressure to measure force or weight. It consists of several parts: an air supply which provides a regulated and consistent airflow; a diaphragm or bellows which is a flexible component that deforms when a load is applied; a nozzle and flapper system which controls the airflow based on the movement of the diaphragm; and a pressure gauge or transducer which measures the air pressure and converts it to an electrical signal.

You can adjust the pressure to measure force or weight on the hydraulic load cell. The pressure can be read on an analog gauge or converted to an electric signal.

Hydraulic Load Cells

Hydraulic load cells work on the principle of hydraulic pressure. They consist of a piston and cylinder filled with hydraulic fluid, and when a force is applied to the load cell, it compresses the hydraulic fluid in the cylinder. The increase in pressure in the hydraulic system is proportional to the force applied.

This pressure change is converted into an electrical signal using a transducer, usually a pressure sensor or strain gauge. The electrical signal is then processed and converted into digital values that can be read and recorded by the end user.

Capacitance Load Cells

Capacitive load cells work by measuring the change in capacitance, which denotes the amount of stored charge. When force is applied to the load cell it deforms the sensor element and changes the distance between two conductive surfaces (usually two parallel plates). This deformation changes the capacitance between the plates.

The load cell has two parallel conductive plates and a voltage is applied across them, creating an electric field. The amount of charge between the plates depends on the gap between them.

As the plates move together the gap gets smaller. This change in gap causes a measurable change in capacitance which is proportional to the force. The electronics in the sensor converts this into an output signal that represents the force.

How to Choose a Load Cell for Your Application

Load cells are used in many industries to provide accurate and reliable force measurement solutions. Whether it’s a strain gauge, hydraulic, pneumatic, or capacitance load cell, each type has its own advantages for different applications.

When choosing a load cell for your application consider:

- The magnitude and type of force to be measured

- Environmental conditions, including temperature, humidity, and cleanliness requirements

- Required accuracy and resolution

- Installation and maintenance considerations

- Compatibility with existing systems and equipment

Massload Technologies: Where Quality Load Cells are Certified

Massload Technologies designs and manufactures high-quality industrial-grade strain gauge transducers for the truck, crane, mining, oil and gas, and industrial markets.

We are the only Canadian load cell manufacturer to achieve VCAP certification (considered the ISO9000 for load cells), and our Quality Management System is externally audited every 3 years.

Every step of our process is tracked and performed by certified technicians, checked to meet specifications, and fully traceable down to the technician performing the task.

Talk to our technical sales team and get to know our portfolio!