What is Considered an Industrial Scale?

Let’s cut through the marketing speak. Industrial scales aren’t simply “heavy-duty” versions of commercial scales—they’re fundamentally different systems engineered for specific application physics beyond simple gravitational measurement.

True industrial scales incorporate:

- Mechanical Force Management: Specialized load introduction methods, constraint systems, and structural designs that maintain measurement accuracy despite non-ideal loading conditions including off-center positioning, dynamic forces, and eccentric loads.

- Environmental Adaptation: Protection systems engineered for specific exposure conditions including washdown procedures, chemical contamination, dust ingress, and temperature extremes that would rapidly degrade standard commercial components.

- Signal Integrity Engineering: Complete measurement chains from mechanical sensing through signal conditioning to final output, designed to maintain accuracy despite electrical noise, ground potential variations, and power quality issues common in industrial environments.

- Integration Architecture: Communication systems, data formats, and control interfaces specifically designed to function within industrial automation environments rather than standalone operation.

The distinction becomes critical in Texas industrial applications where environmental conditions combine with operational demands to create measurement challenges far beyond standard commercial specifications. Construction operations need scales that maintain calibration despite continuous sunlight exposure and temperature cycling that would quickly degrade unprotected systems. Manufacturing facilities require measurement integrity despite vibration profiles that excite resonant frequencies in standard scale designs. Processing operations demand reliability despite washdown procedures that challenge conventional protection methods

How Do Industrial Scales Work?

The fundamental physics haven’t changed since Archimedes, but modern industrial scales utilize multiple technologies to convert gravitational force into useful measurement data:

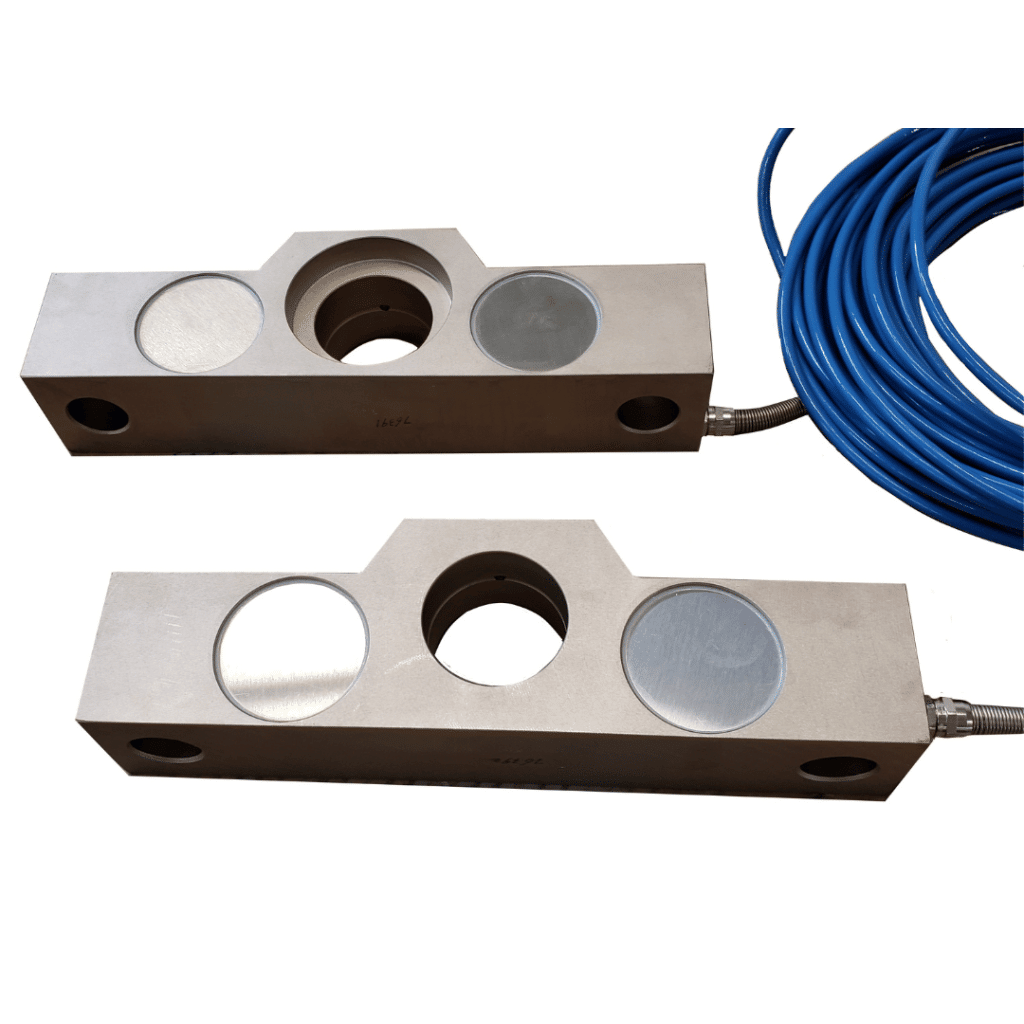

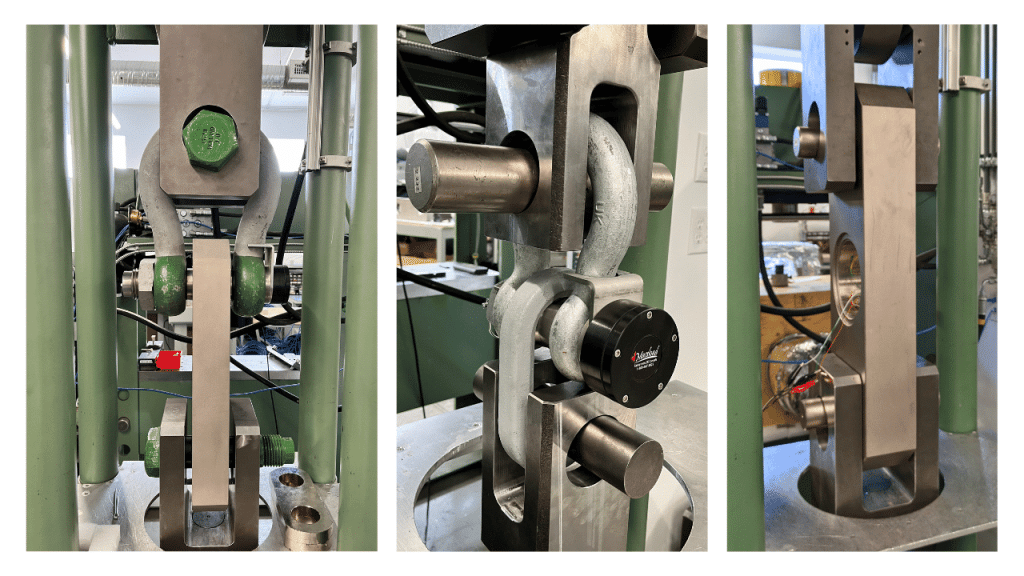

- Load Cell Technology: The primary sensing element in most industrial scales, load cells utilize strain gauges—metallic foil patterns whose electrical resistance changes predictably under deformation. These microscopic resistance changes (typically measured in parts per million) are configured in Wheatstone bridge circuits that generate millivolt-level signals proportional to applied force.

- Signal Conditioning: Those millivolt signals require substantial processing to become useful measurements. This includes amplification (typically 100-1000x), filtering to reject environmental noise, temperature compensation to address thermal effects, and often analog-to-digital conversion for digital processing.

- Mechanical Design Elements: The physical structure of the scale directly impacts measurement accuracy through force transmission paths, constraint systems, and protection methods that determine how applied loads translate to sensor response. Poorly designed structures introduce non-linearity, hysteresis, and drift regardless of sensor quality.

- Environmental Protection Systems: Texas industrial environments present significant challenges from temperature extremes to chemical exposure and moisture infiltration. Protection systems must address these specific conditions rather than relying on generic environmental ratings that often prove inadequate in actual field deployment.

For Texas operations, understanding these fundamentals helps explain why seemingly identical scales with similar specifications often deliver drastically different field performance—the engineering details in force transmission, signal processing, and environmental protection often matter more than basic capacity and resolution specifications.

What Are Industrial Scales Used For?

Industrial scales serve diverse functions across Texas’s economic landscape:

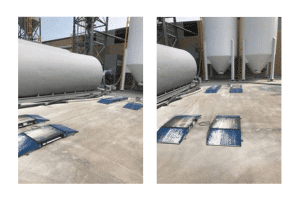

- Material Transfer Verification: Documenting weight during custody transfers between suppliers, processors, and customers—particularly critical in Texas’s extensive petrochemical supply chain where material value directly correlates with precise weight measurement.

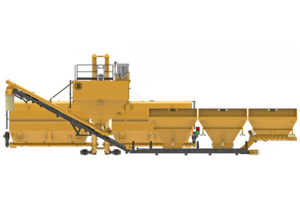

- Process Control: Real-time weight monitoring for batching, blending, and formulation in manufacturing operations where mixture consistency directly impacts product quality and performance characteristics.

- Inventory Management: Continuous monitoring of material quantities throughout production processes, from raw material receiving through intermediate storage to finished product shipment.

- Regulatory Compliance: Weight verification for transportation, environmental reporting, and commercial transactions where documented measurement provides the foundation for regulatory adherence and commercial transparency.

- Safety Monitoring: Critical weight measurement for lifting operations, structural loading, and equipment utilization where overloading could create hazardous conditions or equipment damage.

These applications span industries from oil and gas production through chemical processing, manufacturing, agriculture, and transportation—sectors where measurement accuracy directly impacts operational efficiency, product quality, and regulatory compliance throughout Texas’s diverse industrial landscape.

How Accurate Are Industrial Scales?

Accuracy specifications often create more confusion than clarity in industrial weighing. Simple percentage ratings (±0.1%) or counting divisions (5,000d) fail to capture the complexity of real-world performance factors:

- Environmental Effects: Temperature variations can introduce measurement errors exceeding basic accuracy specifications unless systems incorporate appropriate compensation methods calibrated for actual operating ranges rather than standard test conditions.

- Loading Conditions: Off-center positioning, dynamic forces, and vibration frequently create measurement errors that wouldn’t appear during controlled calibration but significantly affect field performance.

- Time-Based Factors: Long-term stability depends on material properties, mechanical designs, and protection systems that maintain performance despite continuous operation and environmental exposure—factors not captured in basic accuracy specifications.

- Integration Effects: Signal transmission, processing algorithms, and display methods can introduce additional errors beyond the basic sensing elements, particularly in systems spanning significant distances or incorporating multiple processing stages.

For Texas operations, meaningful accuracy assessment requires evaluating complete system performance under actual operating conditions rather than simply comparing laboratory specifications. The distinction becomes particularly important in applications where measurement directly impacts product quality, regulatory compliance, or commercial transactions.